FEATURES

Ultra-low dust, saving a lot of wiping time;

The paper is fine and will not scratch the surface of the object being wiped;

LINTGUARD anti-static film to prevent static electricity and dust generation;

Good dry and wet strength, not suitable for damage;

100% virgin wood pulp with special processing technology, pure texture and high water absorption;

A variety of specifications to meet the needs of different uses.

The paper is fine and will not scratch the surface of the object being wiped;

LINTGUARD anti-static film to prevent static electricity and dust generation;

Good dry and wet strength, not suitable for damage;

100% virgin wood pulp with special processing technology, pure texture and high water absorption;

A variety of specifications to meet the needs of different uses.

APPLICATION

Wipe cleaning of precision instruments such as science and analysis;

Clean the surface of the product with solvent;

Wiping of precision components

Cleaning of printing equipment;

Clean the surface of the product with solvent;

Wiping of precision components

Cleaning of printing equipment;

Packaging of special parts

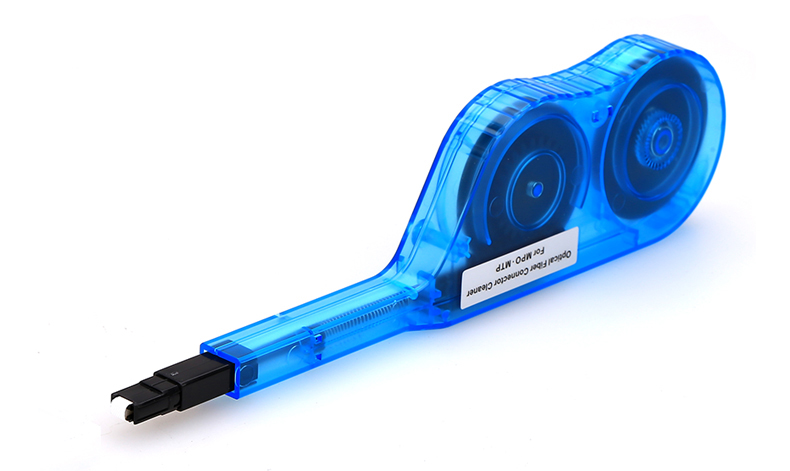

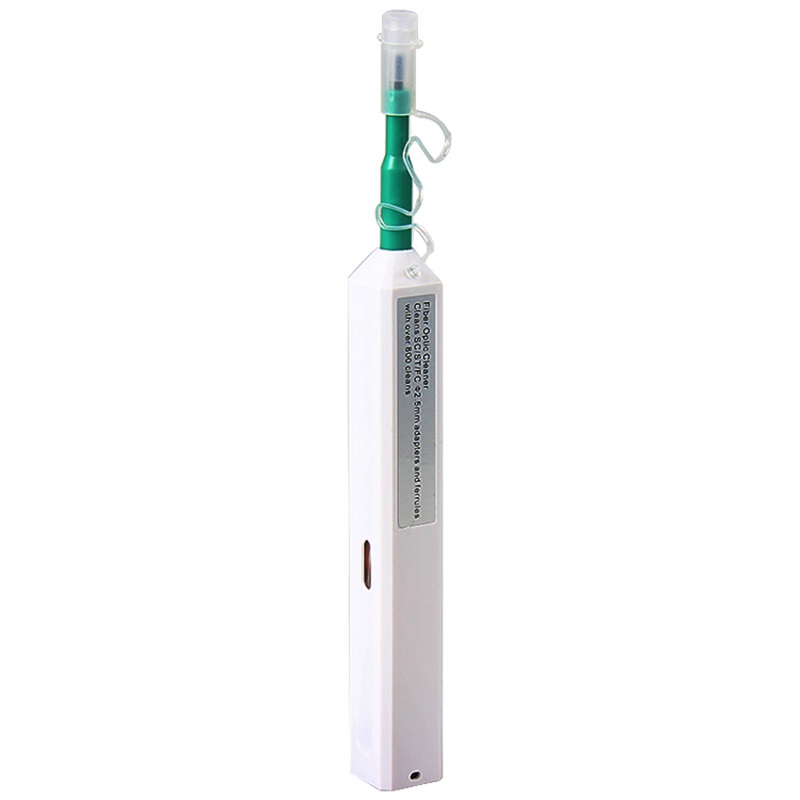

Why Should We Clean the Connectors?

Research has shown over 85% of fiber optic network failures in data centers, campus, and other optical communication facilities are caused by contamination on the optical connector end face.

For best optical performance, it is imperative that all optical fiber connections are clean and free of contaminants. Fiber optic cleaning products is being highly recommended as a kind of very important tool for electrical manufactures. One of the most basic and important procedures for the maintenance of fiber optic systems is to clean the fiber optic equipment.